East Perth Power Station

For a webpage with a documented history of the East Perth Power Station, go to Place:East_Perth_Power_Station_History

A film titled 'Empire Links' that documents the construction of B Station between 1935 and 1938 is available here from the National Film and Sound Archive (NFSA) of Australia. This c1939 documentary was produced by International Combustion Limited of London, the main contractor for supply and construction of EPPS expansion.

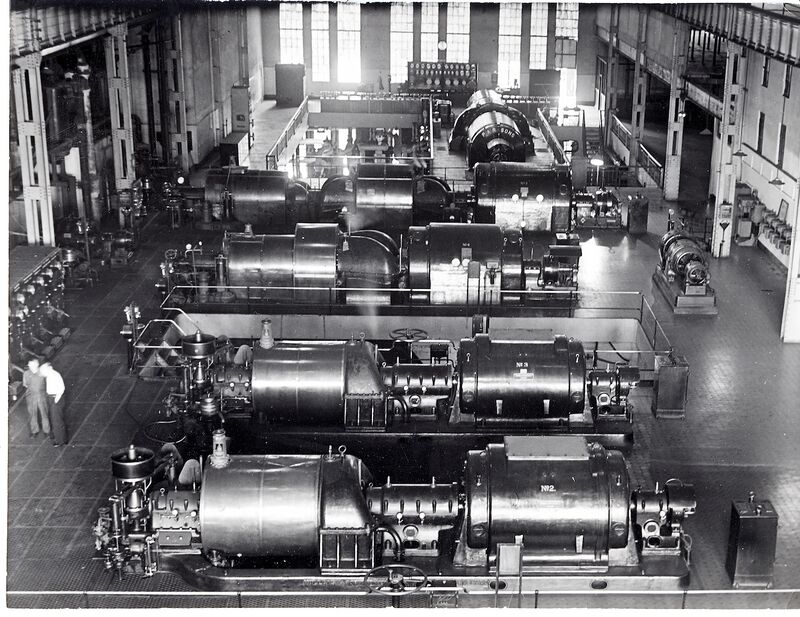

The East Perth coal fired power station (EPPS) was Australia’s first power station built on the 'Independent Unit Principle'. This principle was developed by Mr Charles Merz, a world-renowned electrical engineering expert of the early 20th century. It greatly improved the reliability and efficiency of electric power generation. It was to become the pattern of power station design and layout applied throughout Australia.

EPPS was also the nation’s first power station exclusively employing turbo-alternators for production of electric power. Most of these machines remain in their original locations.

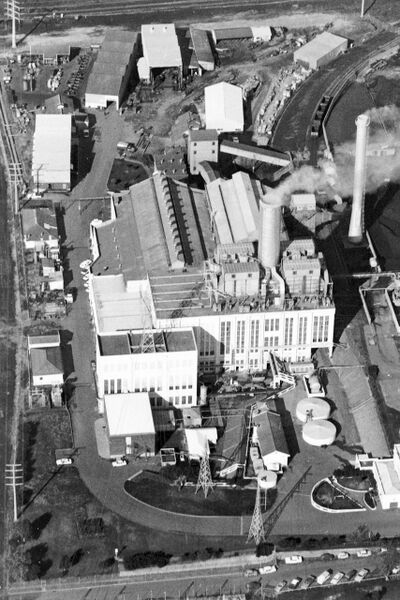

The first two phases of the power station consisted of 40 Hz machinery. By 1943 this frequency was out of step with the rest of Australia so the WA Government decided to convert from to 40 Hz to 50 Hz. To facilitate the conversion, a 40/50 Hz frequency changer was installed at EPPS. When it entered service its 25 MW electric motors were reputed to be the largest in the southern hemisphere. The frequency conversion required widespread modifications to consumers’ electrical equipment. The State Electricity Commission carried out this work between 1951 and 1958.

Construction of EPPS commenced in 1913 with more than 1,300 hardwood piles cut from the Jarrah forests of south western Australia being driven on the site. On top of them was poured a concrete raft to support the power station buildings. The first recorded power export was on 3rd December 1916. From then, until South Fremantle Power Station began operation in 1951, it was the largest power station in the State. In 1981, after 65 years of operation it permanently ceased generating power but remained on power factor correction duty until December 1982.

Engineering Heritage Recognition Program

| Marker Type | Engineering Heritage National Marker (EHNM) |

| Award Date | 19 September 2025 |

| Heritage Significance | Because there are many engineering features still in their original locations, the East Perth Power Station is unique within Australia and a rarity around the globe. Some of the key features are:

|

| Nomination Document | Available here. |

| Ceremony Report Heritage Marker Ceremony |

To be advised. A recording of the presentation on the history of the East Perth Power Station and its heritage marker ceremony held on 27 November 2025 is available here from EA OnDemand. |

| Plaque/Interpretation Panel | Available here. |